V-belt tensioner

306 Products found

-

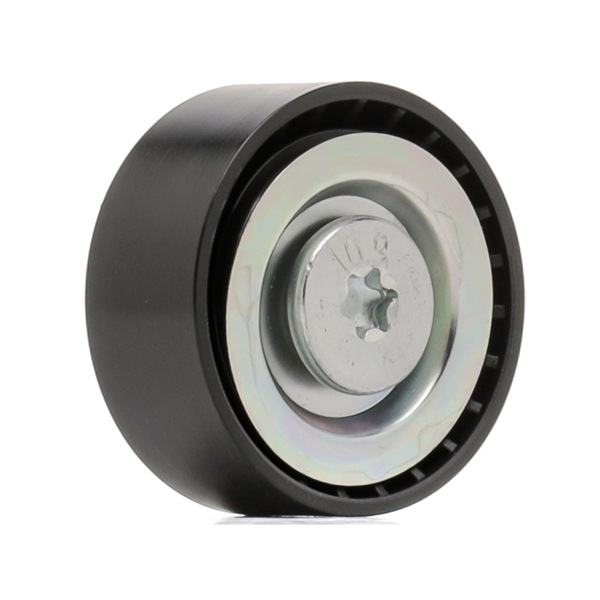

SKTP-0600911STARK, V-belt tensionerWeight [kg]: 0,205; Inner Diameter [mm]: 17; Outer Diameter [mm]: 65;

SKTP-0600911STARK, V-belt tensionerWeight [kg]: 0,205; Inner Diameter [mm]: 17; Outer Diameter [mm]: 65; -

-

SKTP-0600907STARK, V-belt tensionerVehicle configuration line / variant: ; Inner Diameter [mm]: 17; Outer Diameter [mm]: 55;

SKTP-0600907STARK, V-belt tensionerVehicle configuration line / variant: ; Inner Diameter [mm]: 17; Outer Diameter [mm]: 55; -

-

-

-

SKTP-0600733STARK, V-belt tensionerInner Diameter [mm]: 10,2; Outer Diameter [mm]: 65; Suitable for vehicle type: PC (passenger car);

SKTP-0600733STARK, V-belt tensionerInner Diameter [mm]: 10,2; Outer Diameter [mm]: 65; Suitable for vehicle type: PC (passenger car); -

-

-

-

SKTP-0600685STARK, V-belt tensioner

SKTP-0600685STARK, V-belt tensioner -

-

SKTP-0600661STARK, V-belt tensionerStroke [mm]: 38; Tensile Force [N]: 170; Compressive Force [N]: 900;

-

SKTP-0600651STARK, V-belt tensionerOuter Diameter [mm]: 60; Track rollers material: Plastic; Housing material: Aluminium;

SKTP-0600651STARK, V-belt tensionerOuter Diameter [mm]: 60; Track rollers material: Plastic; Housing material: Aluminium; -

SKTP-0600630STARK, V-belt tensionerInner Diameter [mm]: 8; Outer Diameter [mm]: 55; Bolt Head Diameter [mm]: 8; Supplementary Article / Supplementary Info Info 2: with screw;

SKTP-0600630STARK, V-belt tensionerInner Diameter [mm]: 8; Outer Diameter [mm]: 55; Bolt Head Diameter [mm]: 8; Supplementary Article / Supplementary Info Info 2: with screw; -

SKTP-0600598STARK, V-belt tensionerHeight 1 [mm]: 32,0; Belt Pulley Ø [mm]: 65,0; Supplementary Article / Supplementary Info Info 2: with screw;

SKTP-0600598STARK, V-belt tensionerHeight 1 [mm]: 32,0; Belt Pulley Ø [mm]: 65,0; Supplementary Article / Supplementary Info Info 2: with screw; -

SKTP-0600576STARK, V-belt tensionerOuter Diameter [mm]: 27; Track rollers material: Metal; Housing material: Aluminium;

SKTP-0600576STARK, V-belt tensionerOuter Diameter [mm]: 27; Track rollers material: Metal; Housing material: Aluminium; -

SKTP-0600554STARK, V-belt tensionerOuter Diameter [mm]: 67; Number of grooves: 6; Track rollers material: Plastic; Housing material: Aluminium;

SKTP-0600554STARK, V-belt tensionerOuter Diameter [mm]: 67; Number of grooves: 6; Track rollers material: Plastic; Housing material: Aluminium; -

SKTP-0600552STARK, V-belt tensionerWeight [kg]: 0,243; Inner Diameter [mm]: 8; Outer Diameter [mm]: 70; Packaging Depth [cm]: 7,2;

SKTP-0600552STARK, V-belt tensionerWeight [kg]: 0,243; Inner Diameter [mm]: 8; Outer Diameter [mm]: 70; Packaging Depth [cm]: 7,2; -

Advantages of Stark Professional Line V-ribbed belt tensioners

- Unique design. Stark Professional Line automotive components embody the latest developments of the company’s engineers aimed at improving performance and prolonging the service life of the components. Stark Professional Line tensioning rollers can work three times longer than the standard ones.

- Gasket of special shape. It prevents penetration of moisture and dirt inside the components, and reduces the risk of premature wear.

- Extra-strong torsion spring. It is made of modern materials, for example chromium and silicon, and features high stability and resistance to twisting. It is not prone to wear.

- A pulley with smooth surface. It undergoes special treatment and is resistant to abrasion.

- High-quality bearings. They withstand high loads well, and are reliable and durable. In the process of their manufacturing, the most advanced technology is used, and dimensions of the components are carefully checked. This allows achieving the optimal coefficient of friction and decreases the risk of backlash or jamming of the components.

- Efficient damping mechanism. Depending on tensioner type, the damping function is performed by friction discs or by hydraulic devices. Their elaborate design improves the damping properties of Stark Professional Line tensioner mechanisms.

English

English

Русский

Русский

Italiano

Italiano

Français

Français

Español

Español

Svensk

Svensk

Deutsch

Deutsch